Hello, I have a micro/bead lathe. It’s small size and capabilities suit my needs where a larger, full size lathe would not. However I would like to be able to use the lathe for making cups, boxes and hollow items. Too do this I need to be able to secure the wood from one end leaving the other free to work on. The chuck would need to be a maximum of 6cm wide to fit between the lathe and bed. Also it would need a stem to fit into a standard drill chuck. Does anyone have any ideas? Thank you in advance for any help given.

Unfamiliar with ‘Bead Lathes’ I had a look on the internet and conclude that you will not have enough power in your lathe to turn anything of the size you suggest in your list of things to make. If you want to test that thought, mount a blank of the size you need to make one of the items and turn a spigot, the maximum diameter that the drill chuck will hold and just a bit shorter than will go full depth into the open chuck, on one end. Then mount it in the existing chuck and see how you get on. I think that buying a special chuck without doing this test would be a waste of money - which you could put towards a small lathe. Keep the bead lathe for your tiny projects. Happy turning. Philip.

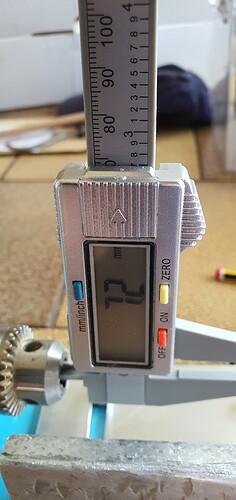

Thank you for your reply. The “chuck” currently on the lathe is basically a drill bit. As such fitting anything into it would be tiny. The boxes I would like to make are about 22mm wide by 77mm. I am planning to use the brass part of fired shotgun shells as the top and bottom of the boxes to make small match boxes. So the chuck itself would need to take a small blank I can then cut down to a 22mm cylinder. The total width of the chuck would have to be 60mm max to fit onto my lathe. The diameter of the blanks would be approximately 40mm max for anything I intend to use the bead lathe for.

Mark

Hi Mark. Can you put up a photo of the machine and a close-up of the existing chuck so that I can understand the problem better.

Philip.

Hopefully these show. The lathe is approximately 14’ in length total and the current chuck is basically a drill chuck. One of the projects I a

m trying is to make a small matchbox using shotgun shell brass ends as the caps for the box and replacing the plastic part of the shells with two wooden tubes that will slide over each other and interlock. I have tried turning the blank down to a size that will fit into the drill chuck, but it is not solid enough to let me hollow out the blanks. So really need a chuck to hold the blank solidly. I have looked at a 1/50 chuck, but concerned the chuck would be too heavy for the 150w motor. no big projects planned.