Hi there, technical question… I recently purchased an AC200WSG bench grinder along with the TORMEK BGK-400 kit - when assembling the two, it looks like I need to raise the BGM-100 mount (on an extra wooden block?) by approx 50mm so that the TTS-100 setter will sit properly on the grinding wheel, when using ‘B’ hole - is that correct? Hole ‘A’ would be fine, but using hole ‘B’ the setter would foul on the underside of the wheel casing. It just seems quite high, and I wondered if I’d got something wrong? Thanks

Update: Went with a 5x5x11cm block under the mount, everything I’ve tried so far seems to now work fine! ![]()

I’'m sure that Colwin Way did a demonstration of setting up a bench grinder with the Tormek jig on Woodworking Wisdom. You could search there to see if you have got it right.

Happy sharpening, Philip.

Hi Philip,

Thanks for the response - yeah, he did, but unfortunately when someone asked (text) about the raised mount (which you could see in the video), the question got skipped! Good video though (as always!)

Hi Neil.

First let me say that I do not own one of these systems and am only working from the instruction manuals you get from Tormek.

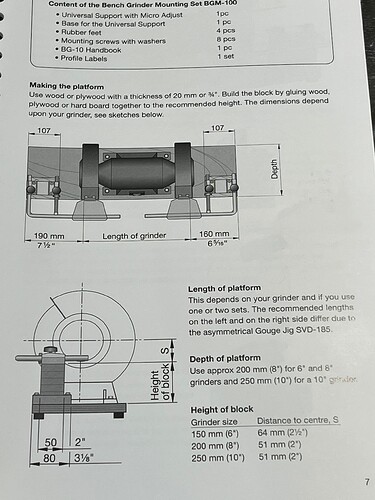

I am amazed that there is no dimension given for the height of the ‘bar’ in relation to the centre line (CL) of the grinder wheel. (All systems I have used specify both the height and the distance in front of the CL (dimension b on the diagram on page 7).

Looking at the diagram on page 7 of the BGM100 manual it is obvious where you set the forward location of the ‘mounting block’ (rear edge) but the height can only be assumed by scaling the diagram. So - assuming that the diagram is to scale, it appears that, with the ends of the ‘tool rod prongs’ set on the vertical CL of the wheel and the TTS100 mounted on hole A, the TTS100 wheels should sit on the grinding wheel in a ‘comfortable’ location, ie below the wheel guards. This set up being achieved by adjusting the height of the Adjustable Mounting Block, using wooden spacers as required.

Sorry that that explanation isn’t very technical - but the best I can do without the bits to hand.

I do note from the video that Colwin’s wooden spacer appears to be little more than a piece of 12mm ply, which suggests that your 25mm block is a bit large, but if it all works and it is comfortable to use then don’t change it.

If you are close to a store you could pop in and check if they have a system set up in their demo area. (I am going to the Basingstoke store on 6 August 22 with our Club and will certainly be having a look for it.)

Hope the sharpening goes well and that you enjoy your turning with the super sharp and repeatable grinds. I find it makes all the difference - and saves tool steel as each visit to the grinder is really only a honing process.

Best wishes, Philip.

Thanks for that, Phil - my block is actually 50mm high, which ends up with the ‘bar’ being just lower than the centre line of the wheels - the TTS100 then sits comfortably when using both holes ‘A’ & ‘B’. BTW, for anyone else trying to set these two items up, I also still have the rubber feet under the grinder, which obviously adds to the height.

All be able might be better English!

You appear to have resolved yourproblem but I bought the same grinder and BGK400 and encountered exactly the same problem. I resolved it by changing the right aluminium oxide wheel for a CBN wheel, doesn’t need the guard an hole B was usable. Also better at sharpening chisels for my limited grinding ability, no bluing them