Hi there, New on here.

Just a quick question.

Is it possible to download, or otherwise obtain from anywhere, a user manual for a Perform CCBB bandsaw , does anyone know?

I seem to have lost mine.

Cheers.

Hi Stevie,

I’ve got a PDF copy if you want one. Just let me know your email address.

Patrick

Hi Stevie

Here is a PDF copy of the Perform CCBB manual for you.

Hope this helps!

Thanks

Abi

Manual.pdf (1.4 MB)

Hi Abi,

I take the yellow Perform range became the Axminster White range. I’ve got the original CCBB manual in PDF.

Regards

Patrick

Thanks for the offer Patrick, I’ve downloaded the PDF from Abi.

Cheers.

Thanks Abi. Downloaded now.

Ok, just seen this Patrick.

Yes, it’s the Yellow perform one.

Here’s my e mail, the instructions may be a bit different from the AWBS one.

I’m sure my original one had info about blade speeds and drive belt tensioning, the one I downloaded from Abi doesn’t have that.

Cheers.

steve@cornishwoodworks.com

Ok, recieved and downloaded.

A big thanks Patrick.

Cheers.

Hi Steve, how are you getting on with your CCBB bandsaw? I only ask because for years I had mine and it never cut straight when using the guide fence, the cut would always wonder off. I have the CCBB II which comes with the quick release lever arm on the guide fence. Whereas the CCBB, I believe comes with a guide fence that has a locking knob. I found that the supplied manual does not explain very well on how to set the CCBB up properly and doesn’t even cover the the CCBB II guide fence that I have or how to adjust it. It wasn’t until I saw one of Axminster Tools’ YouTube videos about the principals on how to set a bandsaw up that I had better success.

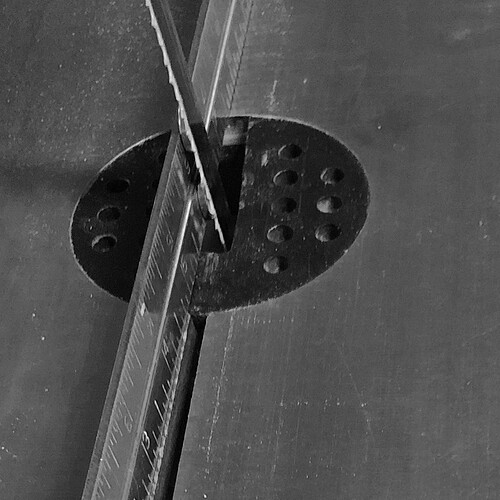

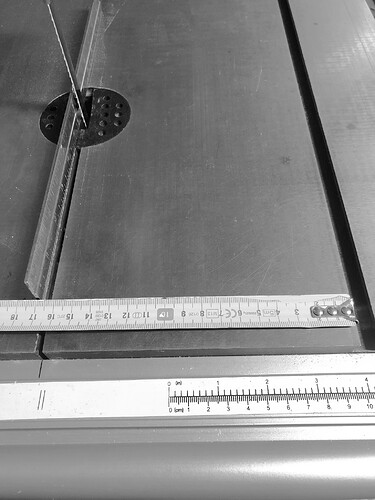

After a bit more playing around with mine I now have it setup cutting super straight lines using the guide fence with no wondering off at all. It wonders off less than 0.1mm along the length of the cut. Essentially I found that you need to set the tables T-slot parallel to the blade. You can do this using Axminster Tools’ Bandsaw Buddy that they suggest in their video or as I did with a couple of thin round magnets on the blade behind the teeth and the ruler from my adjustable square. Ensure the ruler is straight first by looking at it along it’s length and laying flat on top of the saw table. Turning it over and checking both faces. I then adjusted my guide fence so that it is parallel with the table’s T-slot.

Assuming you have first setup the blade guides correctly first. Attached the ruler to blade with the magnets and make sure the blade is adjusted so the ruler floats above the table and free to swing.

Measure the distance at each end of the ruler to the T-slot and rotate the table to reduce the difference in readings by using the slack in the 4 securing bolt holes underneath .

This deviates slightly from AT’s video, in that they set their guide fence parallel to the blade and don’t mention at all about adjusting the parallel accuracy of the T-slot to the blade. However, doing it my way the reading on my mitre fence is now more accurate too.

Because I don’t know which guide fence you have, I don’t know even if the guide fence that comes with the CCBB model can be adjusted independently to the tables T-slot position. If it can’t the only adjustment you do have is adjusting the tables position to the blade with the 4 securing bolts underneath the table.

These are the heads of the 4 bolts underneath my guide fence that you need to slacken off to adjust the fence. I replaced the 4 Allen head bolts with flange head bolts because I found the extra surface area under the head made it easier to adjust especially when tightening the bolts up.

I have written an addendum to the CCBB’s manual which covers how I set my machine up if you are interested.

My addendum,

Replacing the blade in the CCBB bandsaw.pdf (451.6 KB)

I am really pleased with how my machine cuts now and wish I’d managed to sort this out a lot sooner.

I also found an error with original paper CCBB manual that came with my machine and any of the PDF copies about the size of the blade to use. It isn’t the same as the information on the manufacturers label stuck onto the lower access door. The label says on my machine;

Blade capacity: 3/16” to 5/8”

Blade length: 88”

Wheel diameter: 315mm

Whereas the manual says 3/8” to 5/8” and 88-1/4” respectively. Only a minor difference I know but it makes a lot of difference when trying to use AT’s bandsaw blade finder selection tool on their website.

I can highly recommend these blades from AT if they fit your CCBB machine. The varying pitch of the teeth cut very well.

I hope you find this information useful. I’ve also reformatted the CCBB manual so it reads sequentially from page 1 to the end. Whereas the one originally supplied is formatted for printing and makes it difficult to read electronically. I keep wherever possible in Cloud storage PDF copies of all my tools and machines so I have them to hand on my tablet or smart phone.

Here’s a copy of my formatted manual which I’ve also added bookmarks to which allows easier navigation around the document when using a suitable PDF viewer,

CCBB - bookmarked.pdf (1.6 MB)